Whey Texturization: A Way Forward

Texturized ingredients produced by extrusion processing of whey proteins, alone or with other ingredients, provide nutritional and functional benefits in snacks, meat extenders, and other foods.

Cheese whey, once considered “waste” from cheese making, is now a highly sought-after commodity with a significant share of the dairy ingredients market. Through innovations in technology and food science, whey has evolved into an income-producing ingredient for the dairy industry. Technology is again poised to further increase market value for whey proteins through texturization processing and creation of textured co-products.

Texturization is the process of creating structure and texture in biomaterials through the use of various technologies such as extrusion. Food proteins melt and flow at different temperatures and are easily shaped into new structures in an extruder. Vegetable proteins such as soyfoods are texturized by extruding them through an acid or alkali bath into fiber bundles and shaping them through further processing into different structured meat-like products. Soyfoods, including textured soy-based meat alternatives, have grown into a $4-billion industry (Golbitz, 2004). Whey proteins have similar potential for texturization. They have the added advantage that whey protein concentrates (30–80% protein) and whey protein isolates (>90% protein), produced by various filtration processes, do not need alkali or acid bath extraction.

Benefits of Whey Protein

Fortifying with whey proteins improves the nutritional value and consumer appeal of foods such as snacks, cereals, beverages, and meats. The nutritional profile of whey proteins coupled with their functional properties was the basis for our research effort at the Eastern Regional Research Center of the U.S. Dept. of Agriculture/Agricultural Research Service to develop whey-based products containing up to 35% whey, compared to the 2–5% currently found in most snack products. In the past, adding more than 5% whey protein into snacks resulted in loss of snacking qualities (Onwulata et al., 1998).

Adding whey proteins to foods that are low in protein content improves the overall protein profile, particularly in foods derived from grains and beans that are low in lysine. Also, regulatory peptides released by enzymatic proteolysis of whey proteins are potential modulators of intestinal digestion of foods, and may provide nutritive benefits such as nutrient uptake, immune defense, and opioid and antihypertensive activities (Pihlanto-Leppala, 2001). The major whey protein components α-lactalbumin and β-lactoglobulin, contain bioactive sequences which show angiotensin I-converting enzyme (ACE) inhibitory activity.

Whey protein–derived peptides and hydrolysates can be exploited in the development of foods with special health claims, e.g., treatment of hypertension. Recent studies have confirmed the ability of whey proteins or amino acid mixtures of similar composition to promote whole-body and muscle protein synthesis (Ha and Zemel, 2003). Many bioactive components derived from whey fractions, such as glycomacropeptides, bovine serum albumin, and whey-derived minerals, are reported to have specific health benefits, such as enhanced immune function and antioxidant activity, relief of metabolic stress, positive stress responses, improved muscle functionality, greater strength, and improved general health (Ha and Zemel, 2003).

In addition, over the past five years, weight management has become a major issue for health professionals, not only in the United States, but also worldwide. In 2001, the U.S. Surgeon General issued a call to action to prevent and decrease the incidence of obesity (Surgeon General, 2001). Whey proteins, long recognized as high-quality protein sources, may be part of the solution to the growing problem of obesity if sufficient quantities can be included in snacks to replace carbohydrates—proteins provide a net metabolic energy balance and increased weight loss due to diet-induced diuresis. High-protein diets help to suppress appetite (Kappagoda et al., 2004; Denke, 2001).

--- PAGE BREAK ---

Early Texturization: Coextruding of Snacks

Further opportunities exist for whey protein utilization in the U.S. savory snack market, a $20.7-billion industry that has been “nutritionally untapped” (Sloan, 2002). There is room to reduce “empty” calories in snacks by substituting them with nutrient-packed whey proteins.

Our initial research efforts focused on using twin-screw extrusion to include whey proteins in puffed snack products to increase their protein content, e.g., increasing the protein content of corn puffs from 2% to 20%. We have coextruded whey proteins with corn meal, wheat starch, and rice and barley flours, substituting 15–35% of the flour with whey proteins (Onwulata et al., 2001); Fig. 1 shows some of these coextruded snacks. By controlling the physical extrusion processes—operating at high shear, high temperature (100–140°C), and low moisture level (10–15%)—we found that whey proteins can be substituted for starch at up to 25% in corn snacks but with some tradeoffs on snack properties—such products are brittle and crunchy but not expanded (Onwulata et al., 1998). The whey protein–substituted corn meal products are not as puffed as corn meal products alone, because whey proteins hold water and do not react with the starch matrices.

Coextrusion with whey proteins presents other challenges, such as reduction in product quality caused by the collapse of whey proteins within the starch matrix, resulting in increased hardness in addition to reduced expansion. Also, extruding at temperatures ranging from 80 to 150°C may result in loss of protein quality through Maillard reactions and discoloration of product (Camire, 1990). The high temperature needed to puff the products (120–170°C) may prevent or limit inclusion of heat-sensitive dairy proteins.

Improvements over standard high-temperature twin-screw extrusion have been demonstrated by researchers at Cornell University who combined the process with other technologies, such as using supercritical carbon dioxide as a puffing agent to create expanded snacks at temperatures below 100°C. Using supercritical fluid extrusion processing (SCFX), Rizvi and Mulvaney (1993) developed a snack product containing 40–60% whey protein (WPC 34) with an expanded and crispy texture.

Further progress has been made in coextruding texturized whey protein concentrate with an edible biopolymer such as cornstarch without SCFX. For example, extruded product blends containing 65–80% starch and 20–35% whey proteins can be made at low moisture level (10–15%) (Onwulata et al., 2001).

Researchers at Utah State University developed a process for directly texturizing whey protein concentrate (80% protein) with an edible biopolymer such as cornstarch in the extruder. This extruded product blend containing 20–40% starch and 60–80% whey protein concentrate can be added as an ingredient in puffed snacks or meat extenders (Walsh and Carpenter, 2003).

Newer Texturization: Meat Extenders

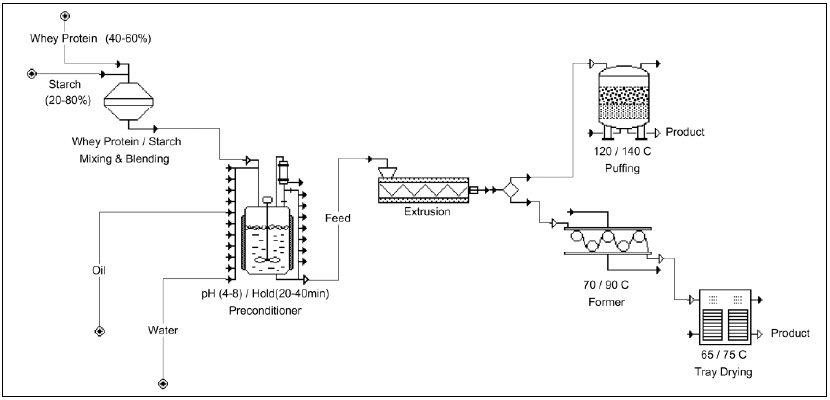

The use of extrusion-texturized plant proteins to impart fibrous texture for use as meat extenders was a significant development in food processing (Atkinson, 1970). Texturized products are combinations of proteins and starches, such as soy flour blended with starch, that are modified by different structure-inducing means, mostly by extrusion processing, to create a chewy or stringy texture (Shen and Morr, 1979). Fig. 2 shows some of the forms of texturized whey proteins that have been produced. The process we use to create the texturized whey protein isolates (Fig. 3) is an adaptation of that used for manufacturing texturized vegetable proteins (Snyder and Kwon, 1987).

Texturized whey proteins show real promise for use as meat extenders and meat alternates. U.S. sales of non-meat proteins have been increasing annually at a rate of 40% (Golbitz, 2003). The majority of this growth has been in textured soy protein; but we are now working on new processes for texturized whey proteins. Meat alternates from texturized whey proteins can provide superior flavor and nutrition in foods for non-meat consumers as well as foodservice applications. In March 2000, school foodservice regulations were modified to allow whey protein concentrate, whey protein isolate, and certain other dairy ingredients to be used as alternate protein products in the meat/meat alternate component in the National School Lunch Program (FNS, 2000). This could be an outlet for texturized whey proteins.

--- PAGE BREAK ---

The conditions needed for texturization and the effects of extrusion processing on elasticity, density, and fiber formation have been characterized for soy protein isolates at moisture levels ranging from 18 to 80% and temperatures above 150°C (Kitabatake et al., 1985). These processing conditions are too high for the heat-sensitive whey protein isolates. Thermal denaturation of the two major whey proteins in whey protein isolate—β-lactoglobulin (50%) and α-lactalbumin (22%)—takes place between 50 and 75°C (Linden and Lorient, 1999). The level of denaturation and subsequent insolubility at pH 7 depend on heating temperature and time and the pH of whey protein (Ennis and Mulvihill, 2000). Loss of protein nitrogen occurs as temperatures increase above 80ºC, and changes in globular protein structure occur at or above 50 and 80ºC with α-lactalbumin and β-lactoglobulin, respectively (Hong and Creamer, 2002). Denaturation of whey proteins is favored at pH 4.6 or lower (Harwalker, 1979).

Researchers at Utah State University found that beef patties extended with up to 40% texturized whey protein concentrate and cornstarch were as acceptable to consumers as 100% beef patties (Hale et al., 2002; Taylor and Walsh, 2002). The texturized patties had less cook loss, diameter reduction, and change in thickness than the all-beef control patties and were not easily distinguishable from them.

Texturized whey proteins can also be made to function as instant thickeners in place of starch and other hydrocolloids, or as firm spread-like thermocoagulated gels (Hudson and Daubert, 2002). Thus, a range of texturized whey protein products can be made to fit into existing lines of successful products on the market.

To create additional versatile texturized whey protein ingredients, further research is needed to understand how texturization affects the nutrients, protein quality, protein availability, flavor, and color of these products. Such studies are being conducted by the Dairy Processing and Products Research Unit at ERRC’s Center of Excellence for Extrusion and Polymer Rheology. CEEPR is housed in a modern pilot plant (Fig.4) with state-of-the-art equipment and instruments to support extrusion processing systems, food polymer science, and engineering, allowing product development from concept to market-demo samples.

The pilot plant includes a 30-mm-diameter Coperion ZSK 30 twin-screw extruder and a 50-mm-diameter APV 50 twin-screw extruder. Products and processes developed with the 50-mm production twin-screw extruder are directly scalable to any desired factory size. Whey protein–based biopolymers can be extruded, molded, and shaped to desired conformation based on rheology/melt properties developed through CEEPR (www.errc.ars.usda.gov/ceepr/).

A patent application has been submitted for the texturization process developed at ERRC. The ARS Office of Technology Transfer (www.arserrc.gov/techtrans) handles all inquiries from interested parties.

The Future

High-moisture extrusion texturization holds the promise for creating texturized whey protein products. In developing a means of creating desirable textural properties, it is imperative that the beneficial properties of whey proteins such as flavor and protein quality are preserved (Onwulata et al., 2003). But taking a cue from texturized vegetable proteins, particularly the market potential, it is a sure bet that resourceful science and business will materialize the idea of texturized whey protein, providing consumers another choice of healthful products. Adding texturized whey proteins in various forms to foods boosts their nutritional profile, reduces the number of calories from carbohydrates, and opens a new market for whey protein suppliers.

With the increasing demand for products with less gums and binders, which are mostly carbohydrate based, and need for consumable or biodegradable wrappers, it is conceivable that modified whey proteins could be molded as foods and food wraps might come into play. Here again, the extrusion and molding technology can be adapted to unique whey protein biopolymers.

Author Onwulata, a Professional Member of IFT, is Lead Scientist, Center of Excellence for Extrusion and Polymer Rheology, and author Tomasula is Research Leader, Dairy Processing and Products Research Unit, Eastern Regional Research Center, U.S. Dept. of Agriculture, Agricultural Research Service, 600 E. Mermaid Ln., Wyndmoor, PA 19038. Send reprint requests to author Onwulata ([email protected]).

References

Atkinson, W.T. 1970. Meat-like protein food products. U.S. patent 3,488,770. Camire, M.E. 1990. Chemical and nutritional changes in foods during extrusion. Crit. Rev. Food Sci. Nutr. 29(1): 35-57.

Denke, M.A. 2001. Metabolic effects of high-protein, low-carbohydrate diets. Am. J. Cardiol. 88: 59-61.

Ennis, M.P. and Mulvihill, D.M. 2000. Milk proteins. In “Handbook of Hydrocolloids,” ed. G.O. Phillips and P.A. Williams, pp. 189-217. CRC Press. Boca Raton, Fla.

FNS. 2000. Modification of the ‘’Vegetable Protein Products’’ requirements for the National School Lunch Program, School Breakfast Program, Summer Food Service Program and Child and Adult Care Food Program. Final rule. Food and Nutrition Service, U.S. Dept. of Agriculture. Fed. Reg. 65: 12429-12432.

Golbitz, P. 2003. Soyfoods sales reach $4.0 billion in U.S. In “Bluebook Update,” April-June, Vol. 10 (3). Soyatech.Com. http://www.soyatech.com/.

Golbitz, P. 2004. Soyfoods sales reach $4.0 billion in U.S. In “Bluebook Update,” April-June, Vol. 11 (2). Soyatech.Com. http://www.soyatech.com/.

Ha, E. and Zemel, M.B. 2003. Functional properties of whey, whey components, and essential amino acids: Mechanisms underlying health benefits for active people (review). J. Nutr. Biochem. 14: 251-258.

Hale, A.B., Carpenter, C.E., and Walsh, M.K. 2002. Instrumental and consumer evaluation of beef patties extended with extrusion-texturized whey proteins. J. Food Sci. 67: 1267-1270.

Harwalker, V.R. 1979. Comparison of physico-chemical properties of different thermally denatured whey proteins. Milchwissenschaft 34: 419-422.

Hong, Y. and Creamer, L.K. 2002. Changed protein structures of bovine β-lactoglobulin and α-lactalbumin as a consequence of heat treatment. Intl. Dairy J. 12: 345-359.

Hudson, H.M. and Daubert, C.R. 2002. Functionality comparison between derivatized whey proteins and a pregelatinized starch. J. Texture Stud. 33: 297-314.

Kappagoda, C.T., Hyson, D.A., and Amsterdam, E.A. 2004. Low-carbohydrate-high-protein diets: Is there a place for them in clinical cardiology? J. Am. Coll. Cardiol. 43: 725-730.

Kitabatake, N., Megard, D., and Cheftel, J.C. 1985. Continuous gel formation by HTST extrusion cooking: Soy proteins. J. Food Sci. 50: 1260-1265.

Linden, G. and Lorient, D. 1999. The exploitation of by-products. In “New Ingredients in Food Processing: Biochemistry and Agriculture,” ed. G. Linden and D. Lorient, pp. 184-210. CRC Press, Boca Raton, Fla.

Onwulata, C.I., Konstance, R.P., Smith, P.W., and Holsinger, V.H. 1998. Physical properties of extruded products as affected by cheese whey. J. Food Sci. 63: 814-818.

Onwulata, C.I., Konstance, R.P., Smith, P.W., and Holsinger, V.H. 2001. Incorporation of whey products in extruded corn, potato or rice snacks. Food Res. Intl. 34: 679-687.

Onwulata, C.I., Konstance, R.P., Cooke, P.H., and Farrell, H.M. 2003. Functionality of extrusiontexturized whey proteins. J. Dairy Sci. 86: 3775-3782.

Pihlanto-Leppala, A. 2001. Bioactive peptides derived from bovine whey proteins: opioid and aceinhibitory peptides. Trends Food Sci. Technol. 11: 347-356.

Rhee, K.C., Kuo, C.K., and Lusas, E.W. 1981. Texturization Vegetable protein products, soy flours or grits. In “Protein Functionality in Foods,” ed. J.P. Cherry, pp. 51-88. Am. Chem. Soc., Washington, D.C.

Rizvi, S.S.H. and Mulvaney, S.J. 1993. Extrusion processing with supercritical fluids. Food Technol. 43(12): 74, 76-82.

Shen, J.L. and Morr, C.V. 1979. Physicochemical aspects of texturization: Fiber formation from globular proteins. J. Am. Oil Chem. Soc. 56: 638-708.

Sloan, E. 2002. The top 10 functional food trends: The next generation. Food Technol. 56(4): 32-57.

Snyder, H.E. and Kwon, T.W. 1987. Protein products. In “Soybean Utilization,” ed. H.E. Snyder and T.W. Kwon, pp. 130-136. Van Nostrand Rheinhold Co., New York.

Surgeon General. 2001. The Surgeon General’s call to action to prevent and decrease overweight and obesity. U.S. Government Printing Office, Washington, D.C. www.surgeongeneral.gov/topics/obesity/default.htm.

Taylor, B.J. and Walsh, M.K. 2002. Development and sensory analysis of a textured whey protein meatless patty. J. Food Sci. 67: 1555-1558.

Walsh, M.K. and Carpenter, C.E. 2003. Textured whey protein product and method. U.S. patent. 6,607,777.