Getting Creative With Hydrocolloids

The growing trend of integrating science into the culinary kitchen is pushing the boundaries of food ideation in both the restaurant and retail food spaces.

One of the main challenges facing creative professionals in the field of food product development is the need to develop novel and differentiated products in a highly competitive marketplace. This is true both for the chef toiling in the kitchen and the product development scientist working at the laboratory bench. In both cases, commonly available ingredients are being transformed into value-added finished dishes, which command a premium in the market. In the culinary world, the supply truck delivers staple ingredients (e.g., flour, sugar, milk, meat, etc.) to the back of the house. In corporate food product development, staple ingredients are delivered to the receiving dock. In both situations, it is the union of technical skill and creative talent which leads to food products that are desirable and marketable.

It is at this point that the two worlds have traditionally diverged, as the respective approaches, tools, and goals of these two disciplines have historically differed. More recently, however, the growth of technical or modern/progressive cuisine has resulted in food science making its way into some of the world’s greatest kitchens (Vega and Ubbink, 2008; Tarver, 2010). The growing trend of integrating science into the kitchen has led to a flourishing of creative possibilities both in the culinary kitchen and, consequently, the lab. This cross-pollination shows immense promise in pushing the boundaries of food ideation in both the restaurant and retail food spaces.

Traditional Texture Manipulation

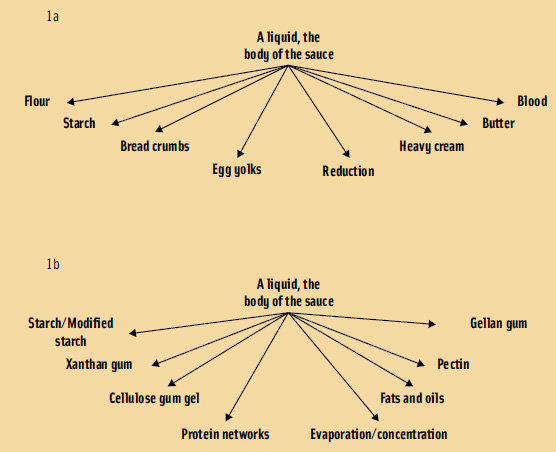

The challenge of controlling and creating texture in foods is universal in both the kitchen and the laboratory. However, the approaches can be fundamentally different. In developing a sauce, for example, the chef traditionally turns to staple kitchen ingredients such as flour, starch, and/or cream or techniques such as reduction in order to achieve the desired texture and flavor (a selection of various culinary techniques and ingredient choices can be seen in Figure 1a). In contrast, the pantry that is available to the food scientist is much broader (Figure 1b). Starch and evaporation/reduction may be common in both approaches, but food scientists also have the additional option of using hydrocolloids, such as xanthan and cellulose gums, to control aqueous rheology. The differences in these two approaches are rooted in tradition, end-use, production, and shelf life, (i.e., stability in the kitchen is measured in terms of hours/day, and practicality is governed by the ability to prepare food products on a relatively small, counter-top scale). In contrast, the food scientist is looking for stability measured by weeks, months, and in some cases years, and practicality often is measured in terms of industrial volume and scale (Barham, et al., 2010).

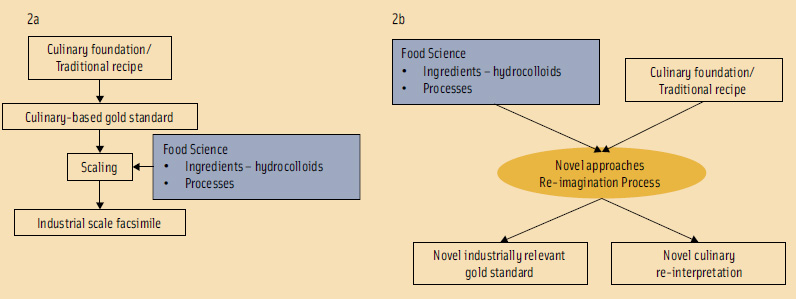

The traditional point of overlap between the culinary world and the realm of the food scientist has been the process of taking a gold-standard recipe and scaling it up for production in a manufacturing environment—what I call the linear approach to food ideation (Figure 2a). The challenges of scaling bench-top formulations are manifold and are well beyond the scope of this article. However, one of the main roles of hydrocolloids is facilitating the scaling process, which allows for the production of product on an exponentially larger scale than that developed at the original culinary bench (i.e., an industrial scale facsimile). It is within this context that hydrocolloids have, and still find, utility in preserving uniformity in texture, maintaining product quality, and improving organoleptic and functional attributes, among other benefits.

--- PAGE BREAK ---

New Creative Techniques

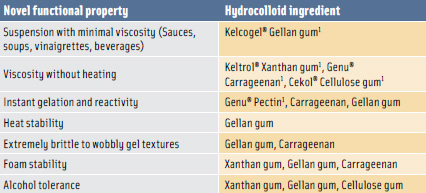

In contrast to the linear food ideation model described above, a new dynamic is changing how food ideation takes root both in the kitchen and the lab. In the culinary world, the constant drive for creative food ideation has led to the adoption of commercial hydrocolloids—a trend that has been taking place for approximately 15 years in the rarified world of haute cuisine (Vega and Ubbink, 2008; Barham et al., 2010). In addition to the beneficial attributes described above, additional functional properties have captured the imagination of chefs and have led to an explosion of culinary creativity (Table 1).

The ability to create liquid suspensions with minimal viscosity using gellan gum is a novel alternative to traditional culinary techniques where suspension is a result of increased viscosity. Thickening agents that do not require heating to develop texture, such as xanthan gum and cellulose gum, present interesting alternatives, particularly in consideration of the impact on flavor that heating plays using the traditional culinary techniques of cooking out a roux and/or gelatinizing starch with heat.

T he introduction and application of low-methoxyl conventional and amidated pectins in the kitchen have broadened the traditional culinary role of pectin by allowing for texture (viscosity and gelation) to be created through calcium-mediated mechanisms, rather than the standard conditions associated with high-methoxyl pectins (high solids levels and acidity). A testament to this explosion in creativity is the near simultaneous publication of a series of highly respected cookbooks in 2008—The Big Fat Duck Cookbook (Blumenthal, 2008), Under Pressure (Keller et al., 2008) and Alinea (Achatz, 2008). The significance of these three cookbooks is reflected in the fact that they were the only books nominated for the 2009 James Beard Award in the category of Cooking from a Professional Point of View (Anonymous, 2009).

Bringing Disciplines Together

This new direction in cuisine has had a two-fold effect. The first is that the application of hydrocolloids requires a certain degree of technical knowhow, which has led to greater collaboration with food scientists—thereby laying the foundation for a cross-pollination of ideas. Successful control of rheology using hydrocolloids requires a thorough understanding of various aspects of science, including polysaccharide chemistry, physical-chemical characteristics of food systems (pH, dissolved solids levels, dissolved ion concentrations), as well as the various tools that influence these molecules and systems (buffer systems, sequestrants, etc.). Indeed, so pronounced is this need that the final third of The Big Fat Duck Cookbook is written by more than 20 scientists and includes sections focusing on flavor, aroma, sensory perception, gelling agents, and emulsions/emulsifiers (Blumenthal, 2008). For the sake of clarity, the Alinea cookbook includes a primer on the “postmodern pantry” and includes a glossary of technical terms such as gellan gum, lactic acid, transglutaminase, and xanthan gum (Achatz, 2008).

According to Corey Lee, Chef/Owner of Benu (formerly Chef de Cuisine of The French Laundry Restaurant), it is “becoming a … prerequisite these days for chefs to really understand the science behind what they are doing” (Lee, 2010). This growing need for collaboration is an opportunity to create bridges between thought-leading chefs and technical ingredient manufacturers, which is the foundation of the CP Kelco Culinary Inspired Technical Innovation program, which aims to develop novel applications of hydrocolloids both in the kitchen and the laboratory with the goal of furthering creative food ideation (Hallock, 2009).

--- PAGE BREAK ---

The second main benefit is the fact that this collaboration has led to a reorganization of the role that food science ingredients and processes play in the food product development process—giving rise to the multiple input approach to food ideation (Figure 2b). In contrast to the linear approach of food ideation, where hydrocolloids play more of a role in scaling-up gold standard formulations (Figure 2a), the multiple input approach places hydrocolloids squarely in the initial innovation stage as a source of inspiration at the outset of the conceptualization process. The result of this new positioning is that increasingly novel concepts can be developed based on the functionality of the hydrocolloid being used. Moving hydrocolloids from the transactional role seen in the linear approach (Figure 2a) to the new focus seen in the multiple-input approach (Figure 2b) opens up new possibilities in terms of re-imagining food and thereby creating new possibilities in the kitchen and in the lab.

Case Studies in Creativity:

Gellan Gum

To fully appreciate the multiple-input approach to food ideation, let’s turn to two case studies as illustrated through the application of gellan gum. As mentioned above (Table 1), one of the truly novel functional properties of low-acyl gellan gum is its heat stability at low-use levels. Due to pronounced hysteresis, where the melting temperature is significantly higher than the set temperature, it is possible to create gelled systems that do not melt under extremely warm temperatures (i.e., >80°C). It is possible to continuously heat a dessert gel with a torch without melting the gel structure. This functional property has been used to great effect in the culinary world in the inspired Flaming Sorbet developed at the Fat Duck Restaurant (Blumenthal, 2008). By integrating low-acyl gellan gum into the sorbet base, heat stability is conferred to the frozen sorbet, which allows it to withstand flaming using whiskey, resulting in a dessert with a warmed exterior and a frozen interior.

A similarly inspired leveraging of heat stability in the industrial food product development lab can be seen in concepts such as freeze-thaw stable, gelled vegetable purées, originally inspired by an educational exchange with Chris Loss of The Culinary Institute of America (Loss, 2008). By combining low-acyl gellan gum, xanthan gum, and guar gum, it is possible to set a blend of vegetable purée and infused cream into a freeze-thaw stable gel that can be microwaved, sautéed, deep-fried, baked, or boiled—a novel, industrially relevant food concept with applications ranging from frozen meals to the efficient use of trimmings in large-scale vegetable processing.

Suspension of particulates in liquid systems with minimal viscosity is another functional property of gellan gum (Table 1) and is the basis of the second case study. Gellan gum “fluid gels” have a very low viscosity when poured or swallowed, but have a very high elastic modulus (solid-like behavior) at rest. These properties allow for a very light mouthfeel when consumed, while providing excellent suspension of particulates such as herbs, spices, beads, etc. As with the Flaming Sorbet example above, this unique functional property of gellan gum has been exploited in the culinary world in the Hot and Iced Tea developed at the Fat Duck Restaurant (Blumenthal, 2008). In this culinary application, a tea-based fluid gel is divided into two fractions, one heated, the other cooled. As the two fractions are fluid gels, they behave like a solid at rest (i.e., when placed side by side in the same teacup they do not mix). The combination of these two immiscible fluid gels (at rest) allows for the presentation of a beverage that is simultaneously hot and cold—a very unique sensory experience. From an industrial standpoint, fluid-gel technology presents the food product developer with novel functional properties that may lead to creative and practical options in food product formulation. This creative application opens up the possibility of suspending everything from herbs and vegetables in dressings and sauces to cocoa, insoluble forms of calcium, and various functional ingredients in beverages with minimal viscosity.

In both of the case studies described above, it is clear that the development of novel food concepts in the kitchen and the laboratory can be successfully developed around the unique functionality inherent to hydrocolloids.

--- PAGE BREAK ---

Future Directions in Innovation

The case studies detailed above indicate that there are areas of overlap where culinary innovation cross-pollinates with food science in a mutually beneficial manner, particularly in the initiation of food ideation in both the kitchen and the laboratory. On a small culinary scale, innovations such as the Flaming Sorbet and the Hot and Iced Tea are both creative and practical. From a food-processing perspective, food concepts such as freeze-thaw stable, gelled vegetable purées and fluid gel suspensions are both relevant and novel. Both of these directions in innovation are grounded in the functionality of hydrocolloids—in these specific cases, gellan gum. As described earlier, similar innovation is possible for a vast array of hydrocolloids, including all of those listed in Table 1.

Not all technologies will move as successfully as hydrocolloids between the culinary and food science worlds; it is difficult to imagine freeze-drying technology becoming commonplace in restaurant kitchens, much as it is almost impossible to picture laborious techniques of the flavor extraction and concentration common to the kitchen playing a role on the industrial processing floor. Notwithstanding the inherent differences, both disciplines bring with them mutually complementary elements—the aesthetic, sensorial, and contemporary aspects of the culinary arts; the functional, practical, and technically reproducible dimensions of food science. The point of overlap between these two worlds is a fertile space in which culinary-inspired technical innovation can flourish and where future food innovation can and will occur in both the kitchen and the laboratory.

By Ted A. Russin, a Member of IFT, is a Scientist at CP Kelco U.S., Inc., 8225 Aero Dr., San Diego, Calif. 92123 ([email protected]). The author thanks Amy Wong, Technical Service, CP Kelco, U.S., Inc. for her assistance in the preparation of the article, which is based on a presentation at the Research Chefs Assoc. Annual Conference and Culinology Expo, Phoenix, Ariz., March 17–20, 2010.

References

Achatz, G. 2008. Alinea. 10 Speed Press, Berkeley, Calif.

Anonymous. 2009. 2009 James Beard Foundation Awards Winners. http://www.jbfawards.com/2009/winners.html#book. Accessed June 11, 2010.

Barham, P., Skibsted, L. H., Bredie, W.L.P., Frost, M.B., Moller, P., Risbo, J., Snitkjaer, P., and Mortensen, L.M. 2010. Molecular gastronomy: a new emerging scientific discipline. Chem. Rev. 110: 2313-2365.

Blumenthal, H. 2008. The Big Fat Duck Cookbook. Bloomsbury, New York, N.Y.

Hallock, B. 2009. Playing with food: Fresh from the lab. Los Angeles Times. April 1.

Keller, T., Benno, J., Lee, C., and Rouxel, S. 2008. Under Pressure, Cooking Sous-Vide. Artisan, New York, N.Y.

Lee, C. 2010. Authors at Google presents Corey Lee. http://www.youtube.com/watch?v=O3AqE0YV4K0. Accessed June 11, 2010.

Loss, C. 2008. The CIA’s menu research & development quarterly. http://menuscience.ciachef.edu/node/168#six. Accessed June 11, 2010.

Tarver, T. 2010. Science + food = fine cuisine. Food Technol. 64(2): 38-45.

Vega, C. and Ubbink, J. 2008. Molecular gastronomy: a food fad or science supporting innovative cuisine? Trends in Food Sci. & Technol. 19: 372-382.